Research at a Glance |

Our group focuses on the investigation of polymer composite and polymer blends, and spans a wide range of area involving polymer physics, polymer processing, polymer chemistry, synthetic polymers and natural biopolymers and we highly emphasis on the combination of fundamental studies and industrial application.

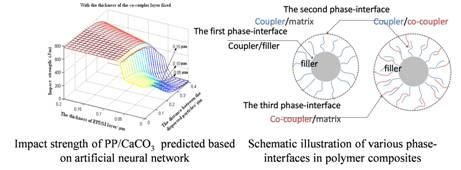

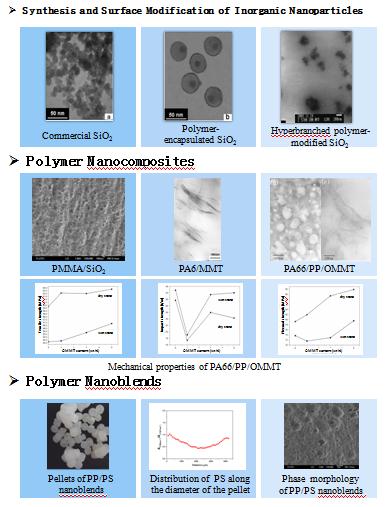

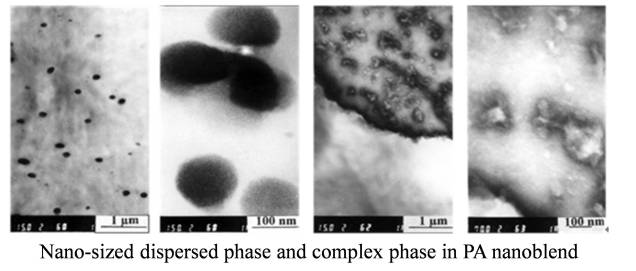

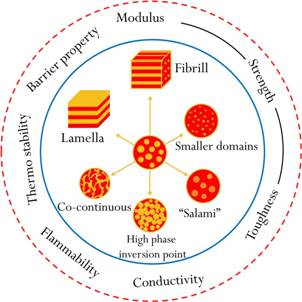

1 高分子共混、复合及纳米材料 Polymer Blends, Composites and Nanomaterials Polymer blends and composites, with high performance and light weight, build solid materials foundation for the development of many major national engineering fields, including transportation, energy, environment, informatics, aerospace, national defense, etc. Recently, polymer nanocomposites and nanoblends, as a result of their nanoscale effect of the dispersed phase, have been found to exhibit much more enhanced properties. Combining fundamental research with engineering application closely, our lab aims to develop advanced methods to synthesize high-performance and multi-function polymer materials, and to build related theories. 1.1 Polymer Composites. We conduct research on the theoretical foundation of composites (including interfacial thermodynamic evaluation of morphology formation, mechanism of interfacial percolation, model establishment and performance prediction etc.), advanced methods to prepare high-performance composites (including design and tailoring of surface, masterbatch methods etc.), and synthesis of multi-functional materials (including flame retardant materials, antistatic materials etc.).

1.3 Nanomaterials

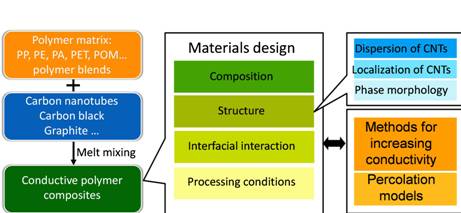

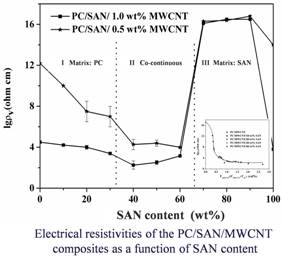

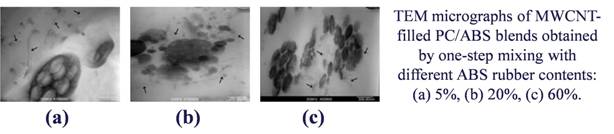

Conductive Polymer Composites Electrical conductive polymer composites have been prepared by melt mixing of carbon-based fillers and a variety of polymers or polymer blends. From the point of view of materials design, the effects of composition, structure, interfacial interaction, processing condition and other factors on materials electrical resistivities have been studied. Methods for increasing conductivity have been explored, and appropriate models and relationships used to guide practice have been established. 2.1Volume exclusion.The volume occupying role of inorganic fillers or polymer dispersed phase has been used to increase the effective concentration of CNTs in polymer matrix, thereby increasing the conductivity of the material. For some systems, a synergy between fillers has been observed. 2.2 Control of the distribution CNTs in polymer blends. By a combination of thermodynamics and kinetics, the control of the distribution of CNTs in polymer blends have been realized, in order to prepare conductive polymer blends. The conductive performance of the material has been improved, and low cost has been achieved at the same time.

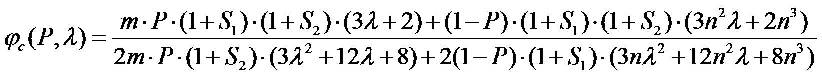

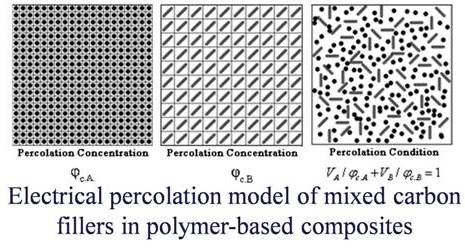

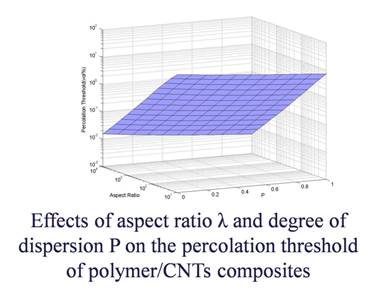

2.3 Percolation models of Conductive polymer composites. Systems of carbon nanotube/carbon black, carbon nanotube/graphite have been studied, a three-dimensional conductivity percolation model of the mixed conductive filler filled polymer has been established. Volume exclusion theory for a single conductive filler has been developed and applied to the mixed conductive filler system, deriving the following condition for the occurrence of percolation: The formula has important guiding significance for the design of conductive composites. The percolation model of the mixed conductive filler system has been used to derive the relationship between percolation threshold, dispersion and aspect ratio of the CNTs : Three-dimensional diagram is shown:

3 纳米纤维和生物材料 Nanofibers and Biomaterials

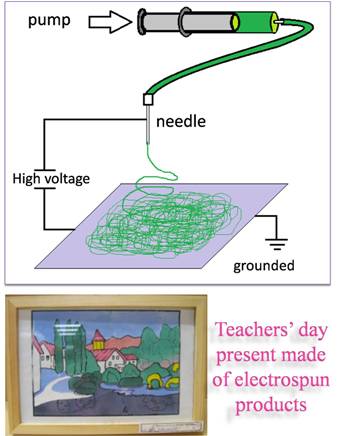

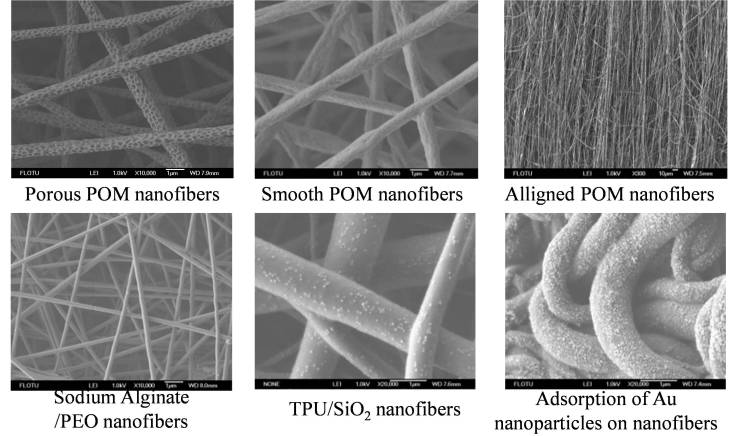

Electrospinning is a recently developed technique for fabricating nanofibers. Electrospun fibrous membrane has high specific surface area, small pore size, and high porosity, and thus has been used or has potential usages in the areas of filtration, sensor, protection material, nano electronic component, enzyme immobilization carrier, tissue engineering scaffold, wound dressing material and so on.

Eggshell membrane protein and POM have been electrospun for the first time in our research group. And we have been conducting research on the electrospinning of natural biopolymers and synthetic polymers, as well as their blends and composites.? We focus on the control of fiber morphology, fiber surface functionization, mechanical properties, biocompatibility, and potential usages of electrospun fibers.

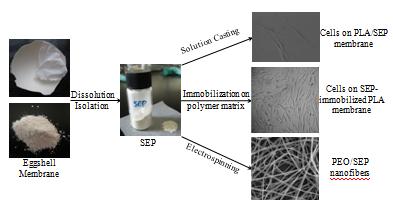

Soluble eggshell membrane protein (SEP) is a newly developed biomaterial by our group. It is extracted from eggshell membrane. Multi-methods of blending, compounding, electrospinning, surface immobilization and pore formation are utilized to study the usage of SEP in the fields of tissue engineering scaffold material, artificial skin, etc.

It has been found that SEP based electrospun fibrous membrane has fine biocompatibility and can support the proliferation and growth of animal cells. It was also a potential hemostatic material.

We also study other natural biomaterials and degradable polymers.

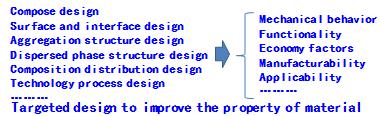

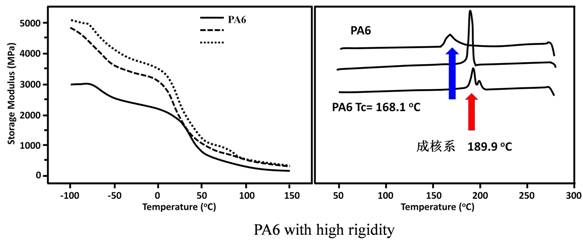

4. 工程塑料高性能化 High performance and functional engineering plastics Engineering plastics, including general type and special type, possess high strength and rigidity and can be used as structural materials at high temperatures. Nowadays, more than 30 kinds of engineering plastics? have been produced by domestic and foreign manufacturers. Researchers have been seeking for new materials with better properties and wider usages because of? the fast improvement of high-tech in 21st century.The only way to achieve this goal is targeted design with economical process based a good knowledge of the relationship between structure and property of materials.Our research group has taken a long time to produce functional engineering plastics and gained rich experiences on them.

Recent years, we focus on the improvement of advanced technologies on engineering plastic. Our work is on the base of combining not only traditional and advanced modified technique but also the basic and application research: Aging mechanisms and anti-aging research; Functionalization and performance enhancement of crystalline plastic; Friction property and self-lubricating mechanism of crystalline plastic; Performance enhancement of ultralow molecular weight PC; Structure and property of new types of PC…

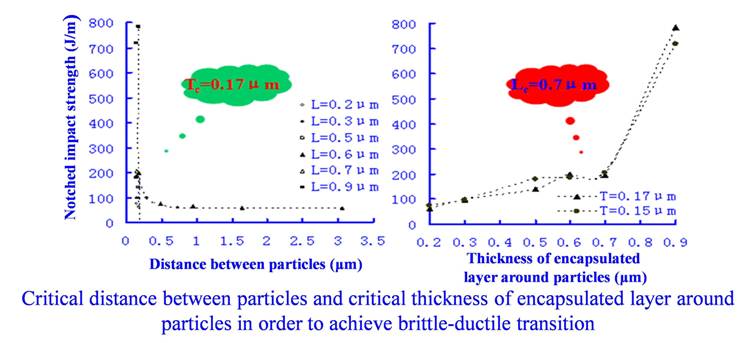

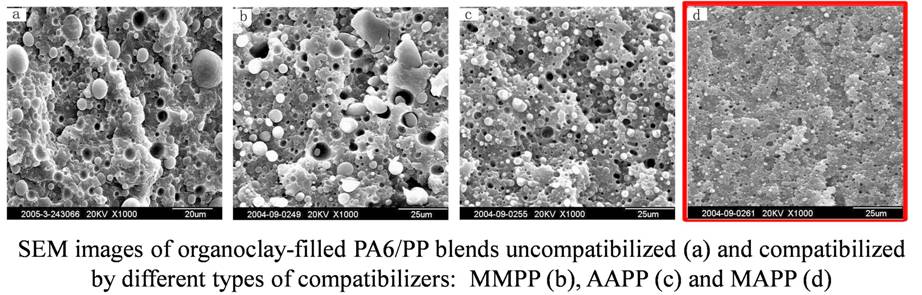

Understanding the strengthening and toughening mechanisms of polymer material is very important to property enhancement. The early toughening mechanism announced by S. Wu has been recognized extensively. We have found the percolation effect of toughness on interfacial layer thickness, which can be used to estimate the brittle-ductile transition of materials regardless of the property of dispersed phase. 5.高分子多组分体系相形态演变规律研究 Morphology Evolution of Polymeric Multicomponent Systems Blending is a common way in tailoring the properties of polymeric materials. By blending two or more polymers, the advantages of different polymers can be combined, leading to optimized overall properties.Most polymer pairs are thermodynamically immiscible, thus phase separated morphology is usually formed after blending. The ultimate properties of polymer blends are closely related to their morphology. Therefore, tailoring the morphology of polymer blends has become an important route in achieving excellent properties. With the development of polymer composites, it has been found that the incorporation of fillers can often induce significant and versatile influences on the morphology of polymer blends.Our group are conducting research on the morp-hology evolution of multiphase and multi-component polymeric systems, focusing on the influences of fillers, compatibilizers and processing conditions. Our study can provide a new route for morphology design of polymer blends, by which desired excellent properties can be targeted.

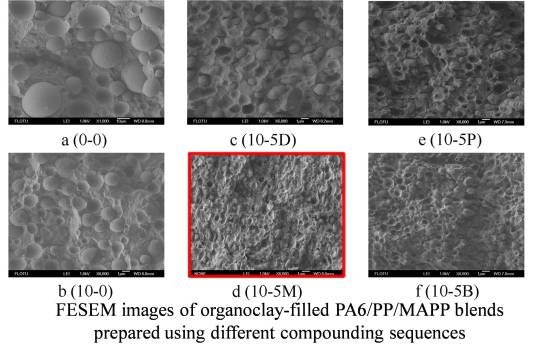

The average dispersed particle size of of organoclay-filled PA6/PP blends can be reduced dramatically by selection of compatibilizers.

Dispersed particle size can be decreased significantly by incorporating organoclay and adjusting compounding sequences.

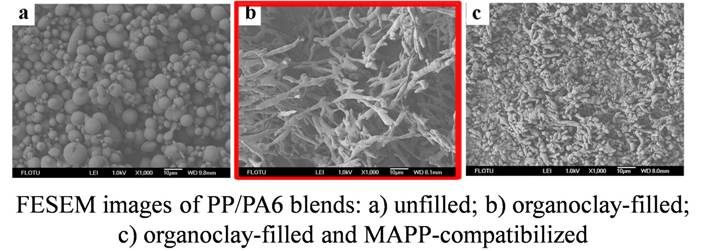

The morphology of PP/PA6 (70/30) blend is transformed in to co-continuous type by adding clay, and PA6 phase emerges into short-rod type by further adding compatibilizer.

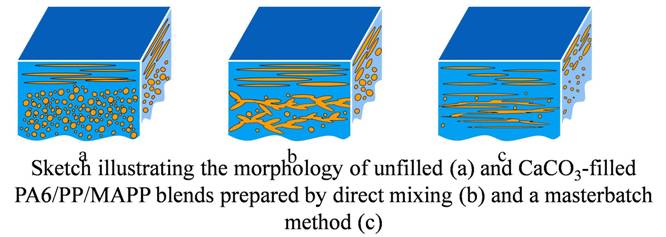

The morphology in the core regions of injection molded specimens changes dramatically by adding CaCO3.

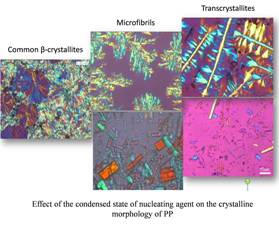

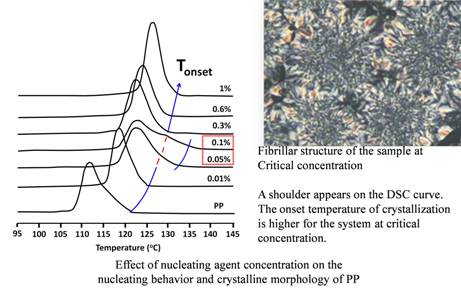

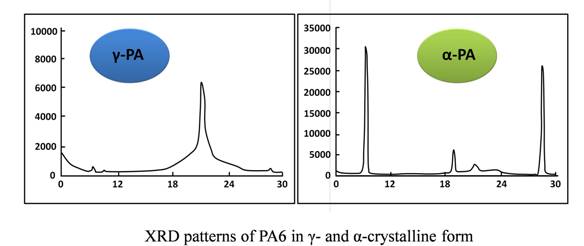

6. 结晶高分子材料的成核行为及高性能化研究 Nucleation Behavior of Crystalline Polymers Crystalline polymers, including PP,POM,PET,PBT, PA and so on, are typical polymorphous polymers. Controlling the crystallization behavior of such crystalline polymers to obtain desired crystal morphology is an important route to develop high-performance and functional polymer materials.

In recent years, research on induced nucleation,nucleationn behavior and performance enhancement of crystalline polymers has raised much attention. We have carried out the following research in this field: New efficient nuleating agent

The influence of nuleating agent on crystallization behavior

Nucleation mechanism and technology

High-performance or functionality of the crystalline polymer materials

|

Designed by Sun Yao·孙尧设计,last updated:15,Aug,2009

版权所有:清华大学化工系高分子研究所,中国 ·北京